Shieldhall Tunnel

7th November 2023

Shieldhall Tunnel

PMP Utilities carried out a few very difficult projects on the Shieldhall Strategic Tunnel for the Costain Vinci JV prior to the tunnelling operation commencing. All projects involved direct input from the Scottish Water Project Delivery Team (Dominic Flanagan and Allan Dougall).

The first of which was to carry out detailed MH and Asset Surveys at various locations of the upstream tunnel section around Queens Park, in the area of the proposed Bifurcation Shaft. This type of project is a core service provided by PMP and involves our specialist rope access survey engineers to safely reach the bottom chamber and survey both it and the shaft, whilst remaining connected to ropes at all times.

Our specialist rope access technicians and survey engineers were the main reason for the Costain Vinci JV choosing PMP Utilities. This was a much safer way to enter the shafts as all personnel could remain attached to a recovery device at all times, as some of the shafts exceed the depth that is able to be provided by standard tripod & winch recovery systems. Also, the quality of the data collected would be 100% accurate and superior to traditional CCTV technology, where a picture is open to interpretation and personal opinions.

The purpose of the surveys was to investigate the general condition of the deep MH shafts and chambers, approximately 20 metres below ground. We were engaged to obtain project critical levels and measurements for the tunnel connections and provide detailed CAD drawings of each of the shafts and incoming/outgoing sewers surveyed.

The success of this initial work package led to a second engagement to manually repair sections of the existing brick egg-shaped sewer under Titwood Road. These remedial works ensured that the sewer was in peak structural condition, prior to the tunnel boring machine passing directly under this main sewer. This work was carried out by our high-risk confined space working teams and supported by our Emergency Rescue Teams. It involved repairs to the fabric by inserting new bricks into areas where they were missing, re-pointing large areas of it and repairs to one manhole chamber.

The last major project we won, was as part of the various work packages to upgrade the local sewer networks and prevent local flooding on the south side of Glasgow. We were awarded the technically challenging contract to remove an old Hydrobrake Flow Control Device in an existing 16-metre-deep split chamber in Thornliebank. The work package also included tasks to remove the top set of ladders down to the first landing to improve the general access/egress for rope access, two redundant penstocks and their control rods and to install a new chain across the existing sewer and core 440mm holes through the existing weir wall.

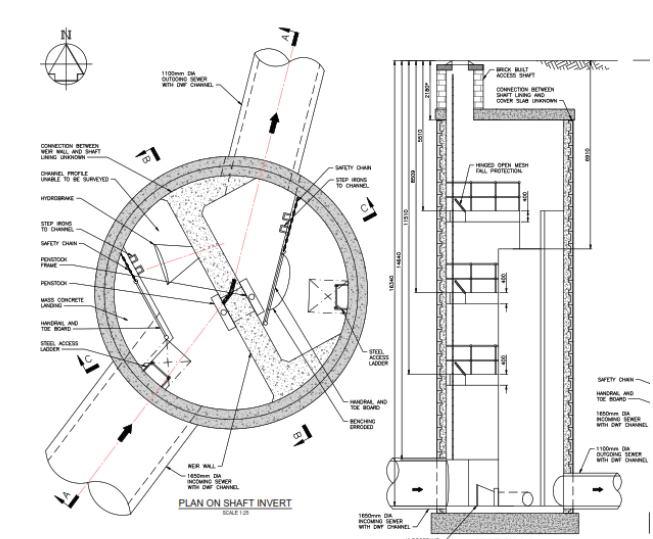

The CVJV Project Team had not used our type of specialist access previously for such complicated work, however, they had an open-minded approach to an innovative and safe working methodology. Being able to demonstrate competency from previous experience on similar types of projects allowed us to develop a robust SSOW for review and comment. All project stakeholders had input to our SSOW and made their own comments for us to review and action. Upon completion of this process which took many weeks to validate, it was deemed safe for PMP Utilities to deliver the package using our unique skills and experience. The first stage of the project was to enter the shaft and survey the existing structure to prepare a detailed survey report for designers to review and formulate a plan to meet the network hydraulic requirements.

All of this work was completed by highly trained and experienced in-house personnel and carried out via rope access technicians and engineers, without the need to excavate and remove old covers, avoided the prolonged disruption to local residents; public transport and other road users, use of expensive diesel operated cranes, our single point of delivery required fewer contractors and less personnel on-site equals a safer site.

|

|

This extract shows the complex general arrangement of the shaft and the restricted working areas. This scope resulted from a pre-works survey carried out by PMP in January 2018. This survey provided previously unknown information and allowed the designers to plan an accurate repair schedule that would work first time with no re-visits for remedial alterations. The project commenced in April 2018 and was completed within the allotted 5 days for all set-up, execution and site clearance. The work we carried out was highly praised for its safety, accuracy and promptness by all stakeholders of the project team.

Further projects that we have been called upon by Scottish Water and current Tier 1 Contractors to provide vital assistance on infrastructure assets include: WGM Engineering at Dalmarnock WWTW to free off two old penstocks on the main inlet sewers. This work was carried out by our IRATA Level 3 rope access technicians, who traversed over a condemned staircase and along a vertical wall by way of drilling in rock anchors to attach safety lines. These same anchors were also drilled into the roof slab to allow for lateral movement across to the control wheels. After freeing off the penstocks by traditional coaxing methods and providing safe isolation, we recommended the retro-installation of hydraulic ram actuators that allowed both assets to be operated at ground level and not by entering a Category 1 confined space. This advice was taken and we re-attended site to complete this installation, which led to further work on various other wastewater projects. George Leslie required our rope access skills and Engineering Survey Team to enter a 23m deep manhole on a main Clyde Valley sewer that discharges at Dalmuir WWTW. The required output from the project was a detailed computerised survey report and CAD model of the existing manhole shaft and chamber and the various staging platforms. Accurate laser measurements were taken to build the CAD model and allowed for 3D rendering of the structure. This data was provided to Scottish Water consulting engineers, to allow their designers to re-design a proposed back-drop connection from a higher level 300mm local sewer. Scottish Water also used our rope access and engineering repair teams to perform a repair to a strategic wastewater pumping station in Braehead Shopping Centre, Glasgow. Due to corrosion in an aggressive environment, VJ Coupling rods had separated causing the coupling to drop and creating a gap for pumped effluent to escape from. Normally, repairs at this station require cranes or scaffolding, drawn off by tankers, local car park closures and out-of-hours working. We completed all repairs within 6 hours, saving thousands of pounds in hire costs for tankers, cranes and scaffolding, whilst removing any disruption to the public, as all works were carried out within a small secure compound. Caledonia Water Alliance called upon our high-risk confined space experience to assist in locating buried manholes and surveying 1.7m and 2.3m diameter sewers as part of the Ayrshire Strategic Resilience C1a Project. Again, the accuracy of our data collection was of paramount importance, as it would be provided to the tunnelling contractors who would use it to programme their levels to bore under both assets. Our Emergency Rescue Teams will be involved in the tunnelling programme when it commences, providing a safe working environment and immediate extraction of any injured persons from the shafts, measuring approximately 25m deep.

|